Gains PP FRP Winding Storage Tank Manufacturing China FRP Vertical Filament Winding Tanks

Overview Gains Pp Frp Winding Storage Tank Manufacturing China FRP Vertical Filament Winding Tanks Product Description F

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | FRP Winding Storage Tank |

| Model | Large Vertical |

| Capacity | Customizable |

| Raw Material | FRP/GRP |

| Shape | Round Tank |

| Eco-Friendly | Yes |

| Certificate | ISO9001 |

| Surface Treatment | Smooth Surface |

| Color | Green or Customized |

| Heat Conductivity | 0.28-3.2m/M.K |

| Compressive Strength | 240MPa |

| Axial Tensile Strength | >=25MPa |

| Impact Strength | 1.5X105t/M2 |

| Keywords | on-Site Winding Large FRP Tanks |

| Density | 1.65-1.9g/cm3 or Customized |

| Product Name | FRP Winding Storage Tank |

| Transport Package | Standard or Customized |

| Specification | DN4500mm - DN25000mm Or Customized |

| Trademark | GJ |

| Origin | China |

| HS Code | 8424899990 |

| Production Capacity | 10000set/Year |

Product Description

Gains Pp Frp Winding Storage Tank Manufacturing China FRP Vertical Filament Winding Tanks

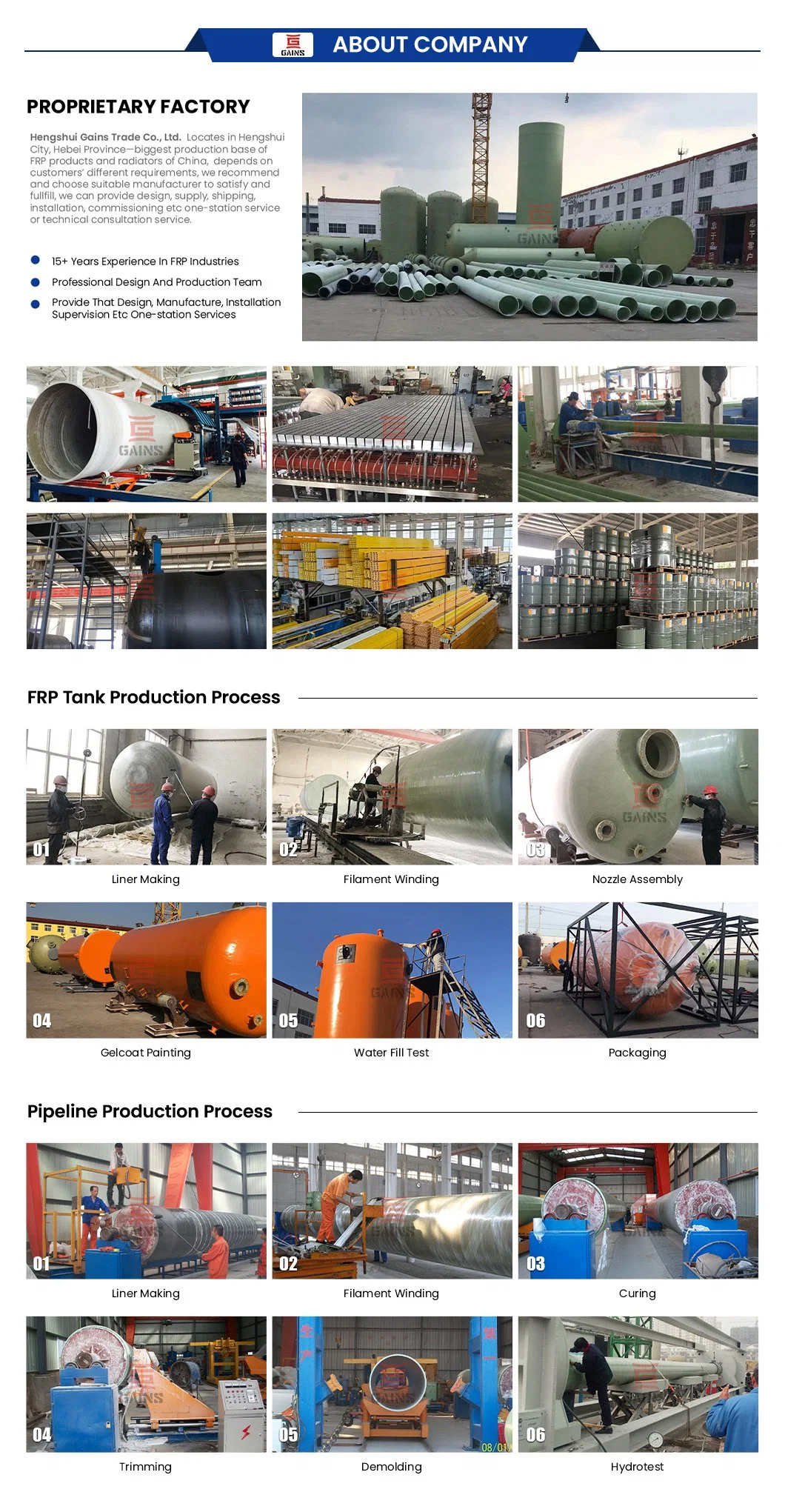

Product DescriptionCraftFRP Large Tank Winding Molding Process Is To Wind The Continuous Fiber (Or Cloth, Tape, Prepreg Yarn) Soaked In Resin Glue On The Mandrel According To Certain Rules, And Then Solidify And Demould To Obtain The Finished Product. The Sewage Treatment Tanks Used In Oil Fields Are Made Using This Process.According To The Different Chemical And Physical States Of The Resin Matrix During Winding, The Production Of Fiber Winding Can Be Divided Into Three Types: Dry Method, Wet Method And Semi-Dry Method.

Based On The Site Condition, Vertical Winding, And Horizontal Winding Can Be Chosen.Large FRP Tanks Manufactured On Site Are Suitable To Store A Series Of Chemical Liquids, Such As Hydrochloric Acid, Sulfuric Acid, Phosphoric Acid, Nitric Acid, Organic Acid, Fluosilicic Acid, Brine, Sewage, Seawater, Potable Water, Etc.

Products Advantages:1.No Need For Transportation, Easy Installation, And Low Maintenance Fees.2. FRP Tanks' Materials Have Improved Interlaminar Shear Strengths, Bend Strengths, Creep Resistance, Wind-Resistant Ability, And Shaking-Resistant Capability.3, Large-Scale On-Site Vertical Design4, Heat-Cured Resin As Its Main Component And Glass Fiber As Its Reinforced Material,5, Adopted Double Filament Mouth To Screw-Wind And Circular-Wind With Excellent Physical Property And Corrosion Resistance,6, Expedient Installation And Without The Need For Maintenance,7, Flexible Design And Rational Wall Structure.Product Parameters

Main Physical Performance of On-Site Winding Vertical FRP Storage Tank

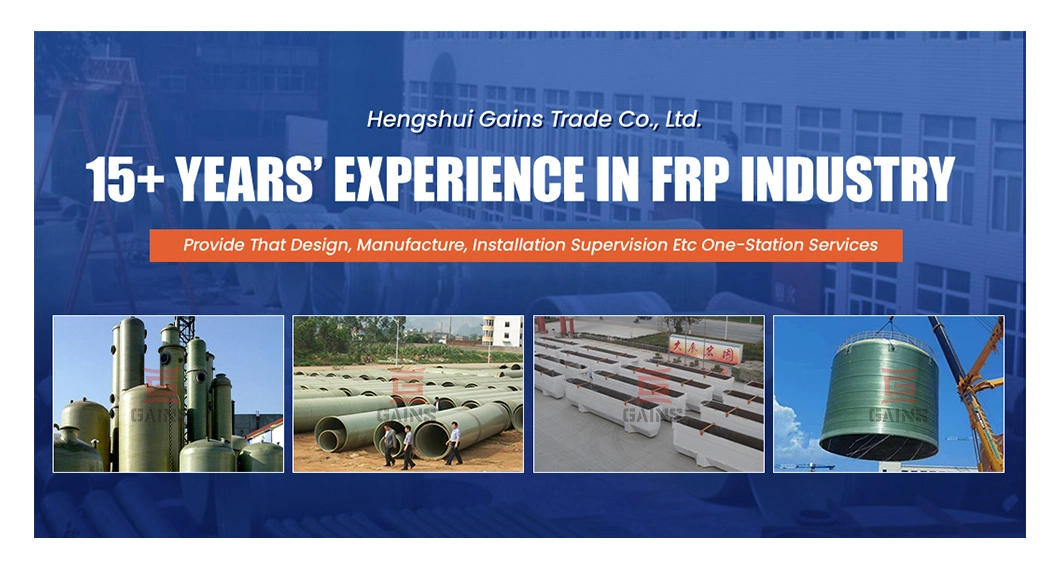

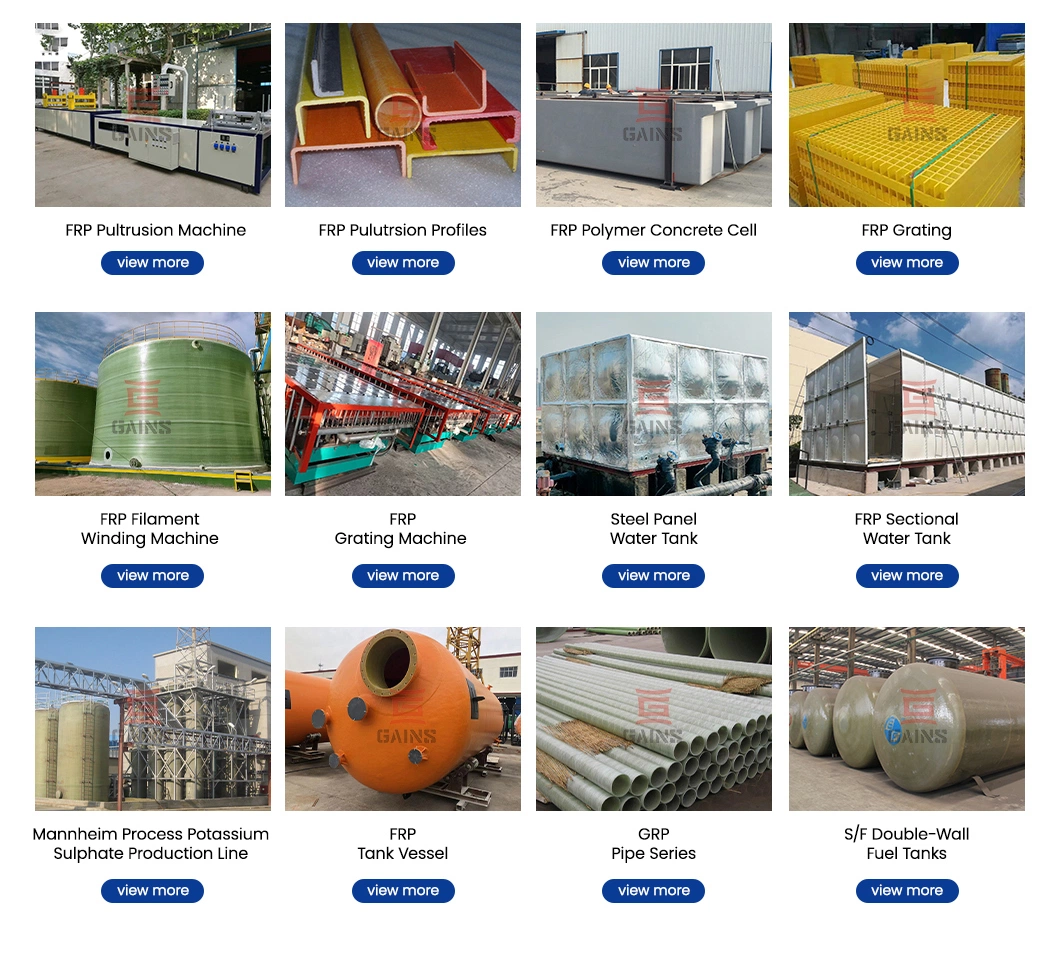

Hengshui Gains Trade Co., Ltd. is Located In Jizhou City, Hebei Province-Biggest Production Base Of FRP Products And Radiators In China, Combines Advantages Of Local Different Industries, Hengshui Gains Trade Co., Ltd. Consists Of Several Large-Scale Manufacturers Of, Depends On Customers' Different Requirements, We Recommend And Choose A Suitable Manufacturer To Satisfy And Fulfill, We Can Provide Design, Supply, Shipping, Installation, Commissioning, Etc One-Station Service Or Technical Consultation Service. From Our Company To Tianjin Seaport Is 300Km, To The Nearest Airport, Is 180Km, Nearest High-Speed Train Station Is 90Km.Our Core Business And Services Are: 1, FRP/GRP Products: FRP Vessel & Tower, FRP (Motor) Pipe, FRP Cooling Tower, FRP Grating, FRP Electrolytic Cells, FRP Septic Tank2, The Whole Set Of FRP Products Production Line And Technology: Computer Control Filament Winding Machine, FRP Protrusion Production Line, Molded FRP Products Production Line3, Radiator4, Electrical Cable5, Sluice Gate Etc Facilities For Water Conservancy6, Rubber Bridge Bracing7, The Whole Set Of Chemical-Making Equipment & Technology: Mannheim Process Potassium Sulfate-Making Equipment & Technology, Titanium Dioxide Production Equipment & Technology

Related Products