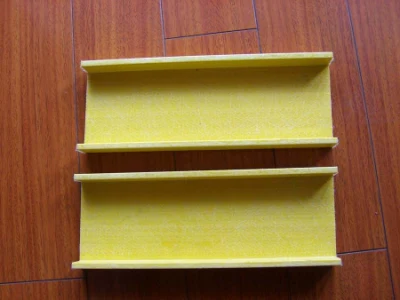

Fiberglass Pultruded Mold Structural Profiles Plastic I Beams for Construction

Overview Fiberglass Pultruded mold Structural Profiles Plastic I Beams for Construction Product Description 1. Precision

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | OK-i-90-11213 |

| Material | Metal |

| Fiber Type | BFRP |

| Type | Diphenyl Ether FRP |

| Catelogue | FRP Pultrusion Profile Mold |

| Transport Package | Wooden Box |

| Specification | Customize |

| Trademark | EMITECH |

| Origin | China |

| HS Code | 8408100000 |

| Production Capacity | 1000 |

Product Description

Fiberglass Pultruded mold Structural Profiles Plastic I Beams for ConstructionProduct Description

1. Precision CNC machining parts strictly follow customers' drawing, packing, and quality requirements.2. Tolerance: between+/-0.01mm;3. The high-tech CMM inspector to ensure the quality;4. Full-Experienced engineers and well professional trained workers;5. Fast delivery time;6. Professional advice for our customers;

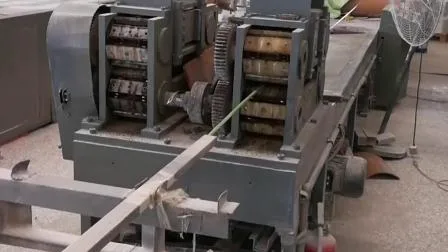

Detailed Photos| Mold name | FRP pultrusion die/ fiberglass Pultruded Mold |

| Design software | UG, Auto CAD, Solidworks, etc |

| Main Services | Mold design, Mold making, |

| Steel Material | P20 , Cr12, Cr12Mov , Cr12Mo1V1, D2 , H13 , 1.2379 |

| Product Raw Material | unsaturated polyester resin/ epoxy resin /polyurethane,resin/phenolic resin /Vinyl resin +/fiberglass/carbon fiber |

| Type | Square tube, rectangular tube, fluted tube, round tube, |

| round rod, flat strip/sheet, I-beam, U-channel, C-channel, | |

| cable tray, protective cover,angle, rails, | |

| gratings ,window&door ,fan blade ,customized shape ,etc | |

| Product Application | industry,communication equipments ,electrical,power industry,spaceflight,fishery,and forestry ,road and bridge construction ,chemical industry. |

| Mold machining equipment | Vertical and horizontal machining center, large surface grinder, |

| milling machine, Deep hole drilling machine, Wire cutting,Lathe, | |

| Machining Process | 1. Steel cutting |

| 2. Fly-cutter | |

| 3. Rough grinding | |

| 4. CNC Milling | |

| 5. Final Grinding | |

| 6. Hole drilling | |

| 7. Polish | |

| 8. Hard chrome plating/Nitriding | |

| 9. Polish again and assemble die | |

| 10. Packing and shipment | |

| Our advantages | 1. Imported steel |

| 2,.Introduced advanced industrial technology abroad, owns industrial technical talents and senior engineers,computer controlled equipment, experienced workers | |

| 3. Reasonable price | |

| 4. Fast delivery | |

| 5. Strict quality inspection system and good after-sales service | |

| Mold surface treatment | Mirror polish, hardening, nitriding, chrome plated |

| Mold life | 100000 meters - 20,0000 meters |

| Mold production time | 25-40 days |

| Certificate | `Iso9001 |

Our advantage of CNC machining:

| Business Type | Beyond the Manufacturer and strong organized ability in the industrial |

| Benefits | 1. Deeper industrial experience at CNC machining parts service for more than 10 years,our customer's requirement is our 1st priority.2. 2D or 3D files are available;3. We trust the quality priority and we insist that good quality should be based on the customers' satisfaction;4. Without any MOQ requirement;5. Faster delivery time;6. Customized size and specification /OEM available7. Near Shanghai Port |

The material

| Materials Accept | Stainless Steel | SS201, SS303, SS304, SS316 etc. |

| Steel | Q235, 20#, 45#, | |

| Brass | C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37) , C28000(CuZn40) | |

| Iron | 1213, 12L14,1215 etc. | |

| Bronze | C51000, C52100, C54400, etc. | |

| Aluminum | Al6061, Al6063,AL7075,AL5052 etc | |

| Plastic | ABS,POM,PC(Poly-Carbonate),PC+GF,PA(nylon),PA+GF,Plastic(acrylic)PEEK, PEI etc) |

- We prefer DHL or TNT express or other air freight between 1kg-100kg.

- we prefer sea freight more than 100kg or more than 1CBM

- As per customized specifications.

Nanjing Emitech Technology Co., Ltd is located in Nanjing City, Jiangsu Province, Which closed the Shanghai.Emtech CNCTechnology is mainly engaged in the pultrusion molds and it's performer design for 15 years. Our Parts are sold to Europe, America, Japan, South Korea, and China in various kinds of industries.At present, Our company has professional quality and testing instruments. We have full OEM Experience worldwide, providing them with One-stop solutions for a broad range of applications. We look forward to cooperating with you!

Our Advantages

1. Precision CNC machining parts strictly follow customer's drawing, packing and quality requirements.2. Tolerance: between+/-0.01mm;3. The high-tech CMM inspector to ensure the quality;4. Full-Experienced engineers and well professional trained workers;5. Fast delivery time;6. Professional advice for our customers;

After Sales ServiceIso9001 certified worldwide CNC parts

We usually provide 12 Months of repair service. If our duty, we will respond to send the new parts.

| Our Processing | CNC center, CNC milling, CNC turning, drilling, grinding, bending, stamping, tapping, |

| Surface finish | Polishing, sandblasting, Zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, imitation gold-plated, |

| Tolerance | 0.05mm~0.1mm |

| QC System | 100% inspection before shipment |

| Drawing format | CAD / PDF/ DWG/ IGS/ STEP |

| Packaging | Plastic bag/Standard package / Carton or Pallet / As per customized specifications |

| Payment Terms | 30 -50%T/T in advance, 70-50% balance before delivery; Pay Pal or Western Union is acceptable. |

| Trade terms | EXW, FOB, CIF, As per the customer's request |

| Shipment Terms | 1)We prefer DHL or TNT express or other air freight between 1kg-100kg.2) we prefer sea freight of more than 100kg or more than 1CBM 3) As per customized specifications. |

| Note | The CNC machining parts are usually custom-made based on the customer's drawings and samples. So we need the Down Payment |

1. What's your advantage?

A: Honest business with competitive price and professional service on the export process.

A: We consider honesty as the life of our company, we can tell you the contact information of our some other clients for you to check our credit. 3. Can you give a warranty on your products?

A: Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you are not pleased with our quality or service.4. Where are you? Can I visit you?

A: Sure, welcome to you visit our factory at any time.5. How about the delivery time?

A: Within 15-35 days after we confirm your requirement.6. what kind of payment does your company support?

A: T/T, 100% L/C at sight, Cash, and Western Union are all accepted if you have other payments,please contact me.

Related Products

-

![Plastic Structural UV Proof High Strength Fiberglass I Beam/ H Beam FRP Pultrusion Profile]()

Plastic Structural UV Proof High Strength Fiberglass I Beam/ H Beam FRP Pultrusion Profile

-

![Fiberglass Reinforced Plastic FRP Pultrusion Profile for Construction Industry]()

Fiberglass Reinforced Plastic FRP Pultrusion Profile for Construction Industry

-

![CE Standard Certificate 63tons Glass Fiber Reinforced Plastic Products of Hydraulic Presses]()

CE Standard Certificate 63tons Glass Fiber Reinforced Plastic Products of Hydraulic Presses

-

![UV Resistant High Strength GRP Channel, FRP Channel Fiberglass Channel]()

UV Resistant High Strength GRP Channel, FRP Channel Fiberglass Channel