BMC SMC BMC Compression Mould Manhole Cover Mould Compression Man Hole Cover Mold for Manhole Cover Fiber Glass Vehicle Mould Lkm

Overview Product Description BMC/SMC/DMC Mould,mold SMC Mould Moulds are produced from High grade steel and with hardeni

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | Mould |

| Processing Method | Forming Mould |

| Technics | Forming Die |

| Process Combination | Progressive Die |

| Manufacturing Technology | Automation Technology |

| Driving Motor Type | Permanent Magnet |

| Mold Cavity Technology | CNC Milling |

| Milling Speed | High Speed |

| Parts Detection Method | Geometric Detection |

| After-sales Service | 24 Online Service; Engineer 1 to 1 Service |

| Warranty of Core Components | 24 Months |

| Machine Type | Punching Machine |

| Key Selling Points | Automatic |

| Showroom Location | Egypt, Canada, United Kingdom, Viet Nam, Mexico, T |

| Mould Material | P20/718/738/Nak80/S136 |

| Certification | ISO9001:2008 |

| Shaping Mode | Compression Mould |

| Machinery Test Report | Provided |

| Power Press Machine | Punching Machine Auto Line |

| Usage | Pressing Metal Products |

| Core Components | Bearing, Pump, Gear, Motor, Gearbox, PLC, Pressure |

| Surface Treatment | Polishing |

| Function | Forming Mould |

| Product | Vehicle Mould |

| Model Number | SMC |

| Transport Package | Standard Export Packaging |

| Specification | Customized |

| Trademark | BESCO |

| Origin | Shandong |

| HS Code | 8428399000 |

| Production Capacity | 1000 Set/Sets Per Mont |

Product Description

Product Description

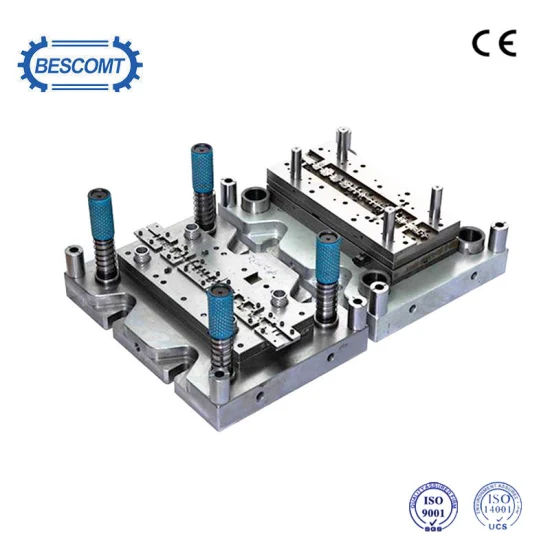

BMC/SMC/DMC Mould,mold

SMC Mould

Moulds are produced from High grade steel and with hardening HRC 48-52.

Beryllium bronsze applied in the punch & Cavity to make the cooling more efficiently.

Moulds were designed for fully automatic production, off-tool parts.

1. Mouldbase

Standardization Use, whenever possible metric standards like LKM for all the mould components. (including guide bushing, guide pin, ejector pin and so on.)

2. Moudbase surface finishing

All plates should be painted with automotive paint blue or green to protect against the corrosion.

3. Cores & cavities

The cores, cavities and inserts made of stainless steel, hardened and tempered up to 45-48 HRC.

Surface finish: Mirror Finish-Diamond Polished.

4. Core wedge blocks

To be manufactured from P20 local steel and heat treatment by gas nitriding.

Wedge blocks need to be located in deep pockets to prevent movement.

5. Steel hardness in general

It is good practice and necessary to have a difference of several points HRC hardness between

sliding steel mould parts to prevent pick up between the steel parts. For example any P20 core slides

or wear plates should be gas nitride.

(Steel material and final hardness certificate will be supplied with the molds.)

The following is mould information for your reference:

SMC Mould Specification Sheet | |

Item | Description |

Mould Material | C45, P20, 718, 2738, Nak80, S-7 etc. |

Mould Base | LKM, HASCO, |

Standard Mould Parts | DME, HASCODME, HASCO |

Cavity | Single / Multiple |

Mould Life | 1,000,000 shots and up |

Plastic material | PP, ABS, HDPE, PC, PVC ect |

Design Software | UG, PROE, Cimatron, Solidwork ect |

Delivery Time | 20-45 days |

Payment | By T/T |

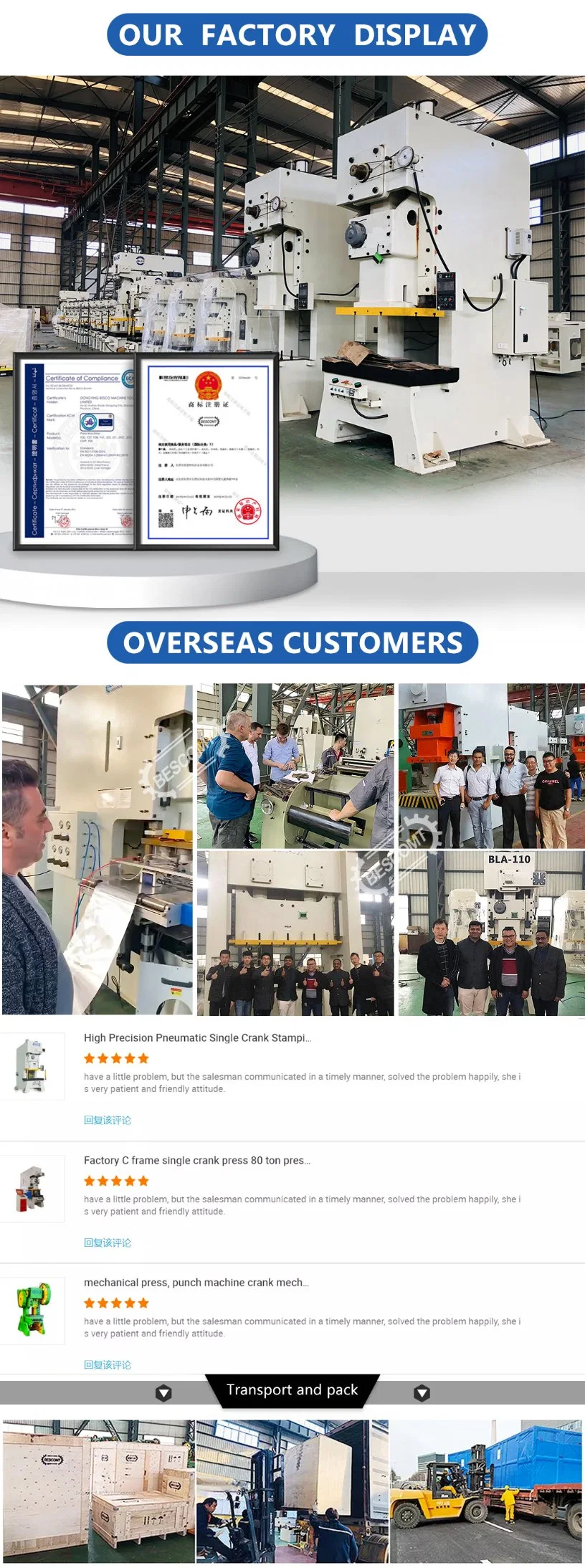

Company Profile

1.Our wooden case is after fumigation treatment. Needn't timber inspection, saving shipping time.

2.All the spare parts of the machine were covered by the some soft materials mainly using pearl wool.

3.The outmost is wooden case with fixed formwork.

4.The bottom of the wooden case has firm iron jack, convenient to handing and transport.

After Sales Service

1.We provide 24 hours on-line service Can contact us by MSN, Skype, Email and Telephone at any timeOur factory also will make DVD to show the operation steps for thecustomer.2.We can send the component by DHL, TNT freelyOur guarantee time is two years, if any component is damaged during guarantee time3.Our factory can send our engineer to the customer's factory install, commission and training freelyThe customer provide the double trip tickets, food and accommodation for our engineer. The customer also can send the engineer to

our factory to learn the operation and maintains freely.

FAQ

1.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis /Conformance; Insurance; Origin, and other export documents where required.

2.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance before delivery 3.Guaranty covers?

Main parts of the machine , wearing parts not included .PARTS DELIVERY. Within 5 days by DHL / Fexed . 4.About our after-sale service:

Customer service 24 hours online, you can send technicians to your country to repair the machine. Buyer shall bear all costs including visa, round trip airfare and suitable accommodation and buyer shall pay usd 100 / day salary.

5.How to replace machine parts?

Parts adopt international brands, good quality, no need to replace within 3-5 years, convenient to buy suitable parts locally.

6.Installation&Commissioning:

Usually solved by video conference, if necessary, can be dispatched to the door installation debugging and maintenance of technical personnel.